Advancing Masterbatch Quality

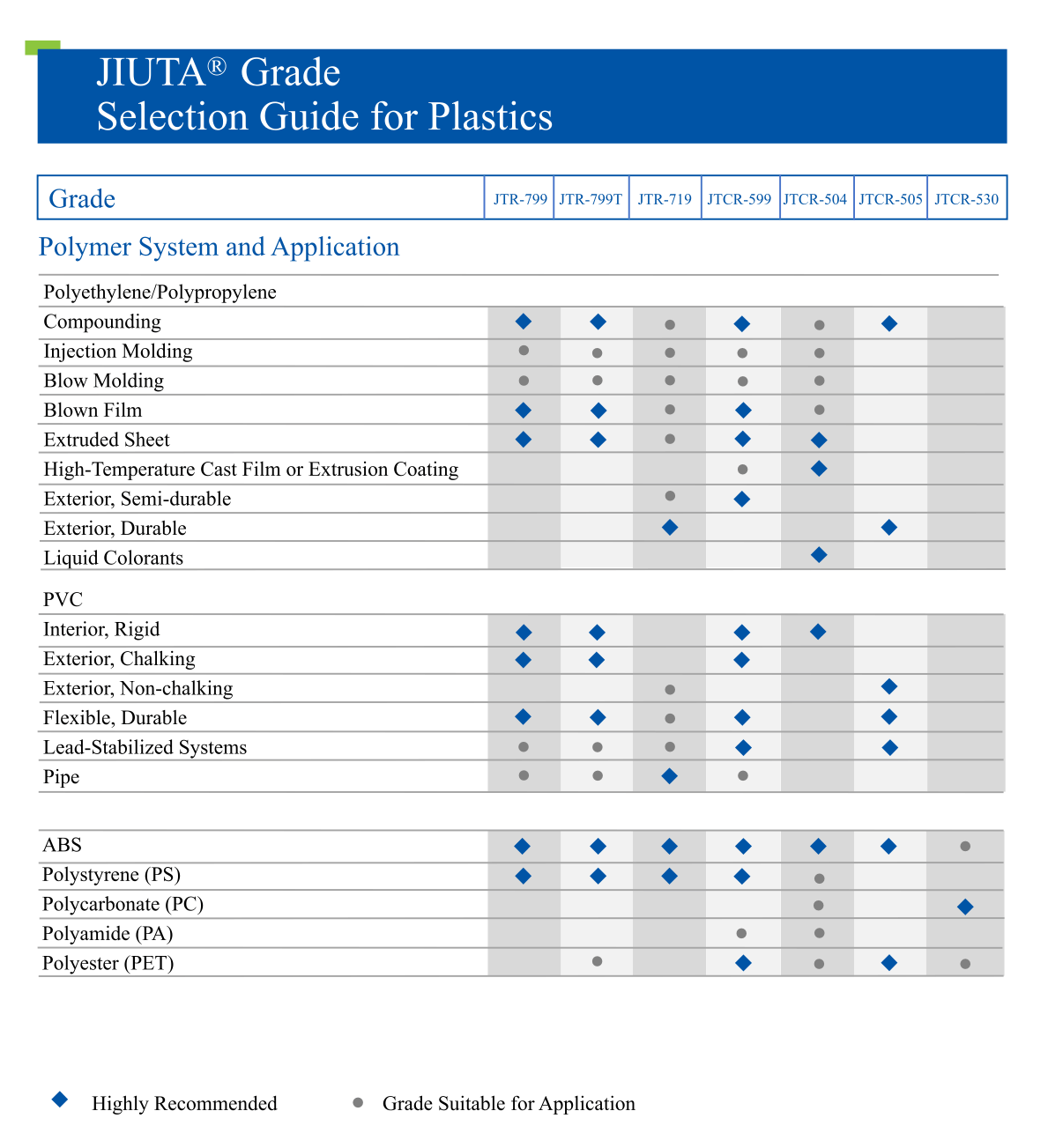

JIUTA's dedicated Research and Development team specializes in advancing Titanium Dioxide (TiO2) for masterbatch applications. Our expertise ensures optimized performance, delivering high-quality TiO2 grades designed to meet the specific needs of the masterbatch industry.

With 50+ testing tools, our R&D Center ensures the quality of titanium dioxide for masterbatch, featuring extruders, FPV testers, and film-blowing equipment.